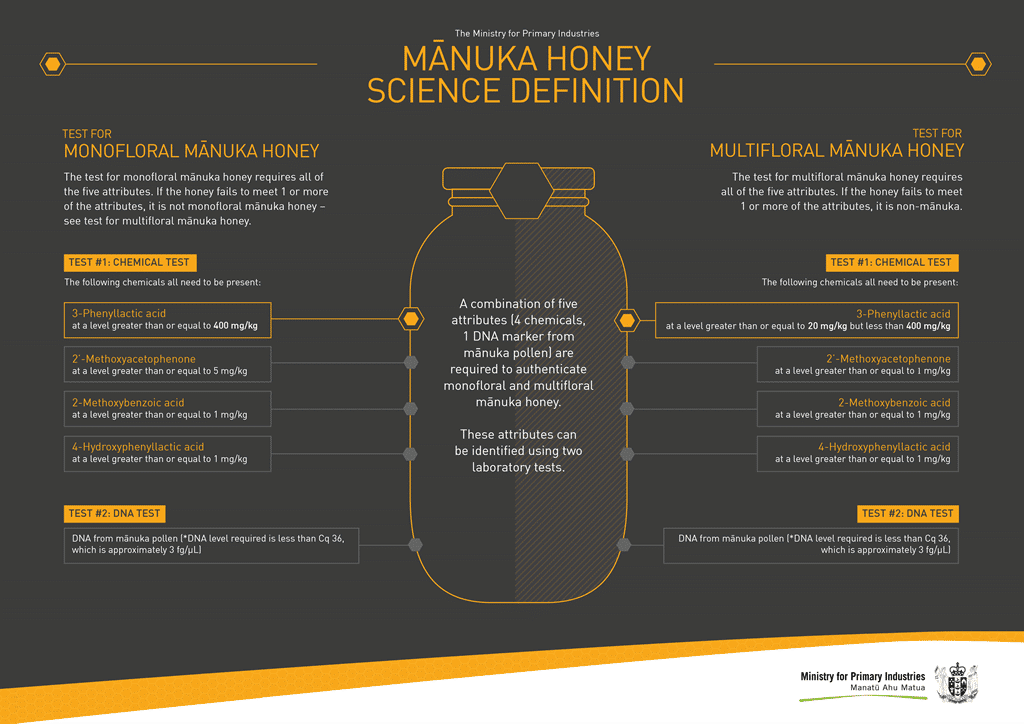

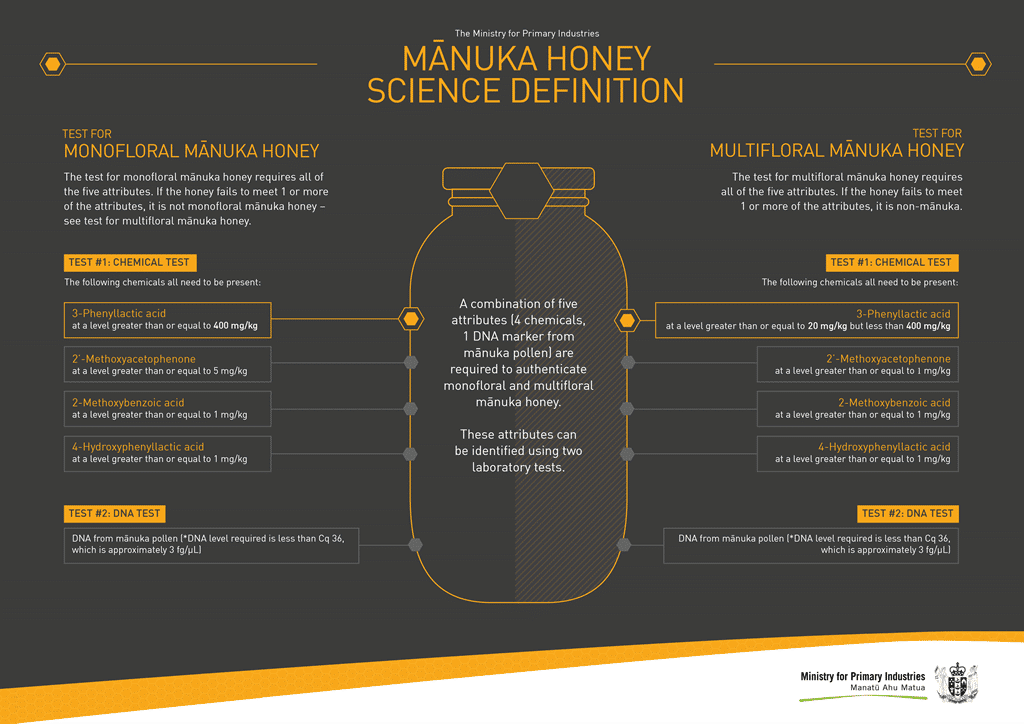

MPI (MINISTERY OF PRIMARY INDUSTRIES NZ) – DEFINITION OF MANUKA HONEY

The MPI in New Zealand has established clear guidelines to determine whether Manuka Honey is a monofloral or multifloral honey. MNZ produces only raw, monofloral MGO Manuka Honey.

At MNZ, we combine expertise, precision, and science to deliver the highest quality raw, unfiltered, and unpasteurized monofloral MGO Manuka Honey. From beekeeping to production, every step is carefully managed to ensure the purity, authenticity, and safety of our products.

Scientific Testing:

All tests are conducted in ISO17025-accredited IANZ laboratories, ensuring the highest standards of accuracy and reliability.

Extensive Authenticity and Quality Checks:

MNZ ensures a fully controlled supply chain, adhering to the strictest guidelines:

MNZ’s monofloral MGO Manuka Honey is raw, unfiltered, and unpasteurized, preserving its natural bioactive properties. With MNZ, you’re guaranteed a product that is:

Manuka honey is a rare and special treasure made in New Zealand by bees that collect nectar from the native Manuka tree. This unique honey is produced only during a brief few weeks each year when the Manuka trees bloom, making it a highly sought-after product.

Harvesting the Nectar:

Quality Testing and Storage:

The Honey Sauna:

Packaging and Labeling:

At MNZ, every phase of production takes place in-house, ensuring that we maintain complete control over the process. From harvesting to packaging, we handle the honey with the utmost care, preserving its natural properties to create a truly exceptional raw Manuka Honey.

Through our meticulous process, MNZ produces a beautiful, raw Manuka Honey that retains its incredible natural properties, flavors, and bioactive benefits—just as nature intended.

Monofloral Manuka Honey is a delicate treasure, requiring meticulous attention and care during production. Its sensitivity to heat demands precise handling to preserve its unique bioactive properties. At MNZ, all testing is conducted following the strict guidelines of the New Zealand Ministry for Primary Industries (MPI), ensuring our honey is truly monofloral and raw.

To confirm the authenticity of our monofloral Manuka honey, we rigorously test for five key chemical markers specified by the MPI. These compounds differentiate monofloral honey from multifloral varieties:

We conduct comprehensive chemical tests to ensure the honey meets monofloral standards, verifying its natural composition and purity.

The DNA from Manuka pollen is analyzed to confirm the botanical origin of the honey, ensuring it is sourced exclusively from the Manuka tree.

As discovered by Professor Thomas Henle, Methylglyoxal (MGO) is the key bioactive compound responsible for Manuka honey’s unique qualities. We rigorously test for MGO levels, as required by the MPI, to ensure our honey delivers the exceptional bioactivity that makes Manuka honey world-renowned.

MNZ also performs extensive testing for contamination, freshness, and potential adulteration, ensuring the safety and integrity of our honey. These tests include:

Every step of the MNZ process, from authenticity testing to final quality assurance, ensures that our monofloral raw Manuka honey meets the highest standards of purity, bioactivity, and safety. With MNZ, you can trust in the integrity and quality of a truly remarkable product, crafted with care and precision.

The MPI in New Zealand has established clear guidelines to determine whether Manuka Honey is a monofloral or multifloral honey. MNZ produces only raw, monofloral MGO Manuka Honey.