MNZ: Excellence in Raw Monofloral Manuka Honey

At MNZ, we proudly process only raw, monofloral Manuka honey, sourced from our own beehives and trusted external beekeepers across New Zealand. All processing, packaging, and labeling occur in our New Zealand-based facility, ensuring that every step adheres to the highest standards of quality and authenticity.

Comprehensive Quality Assurance from Hive to Jar

Reception Process:

Upon arrival at our facility, each honey barrel undergoes a meticulous reception process, including:

- Visual inspections.

- Honey sampling.

- Verification of origin documentation in compliance with the New Zealand Ministry for Primary Industries (MPI) regulations for bee product processing.

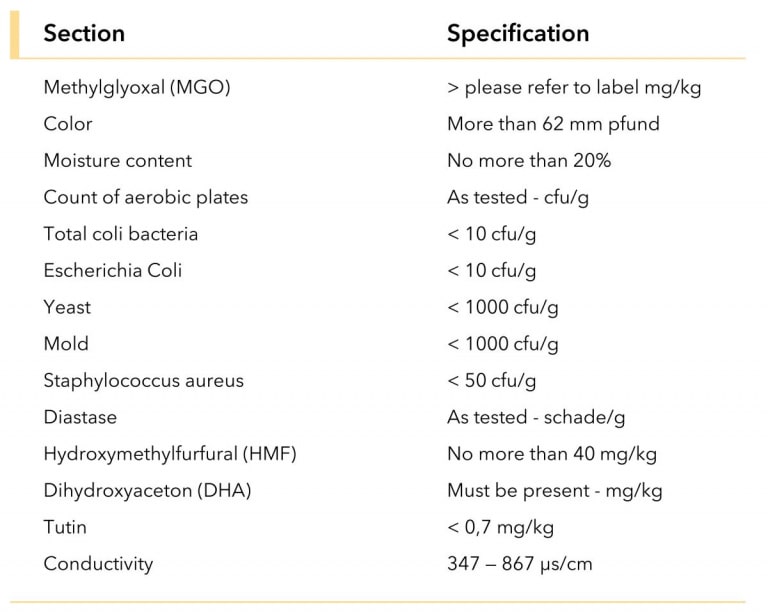

Certified laboratories analyze samples from all barrels to ensure compliance with key quality parameters, including:

- Methylglyoxal (MGO) and Dihydroxyacetone (DHA) content.

- Hydroxymethylfurfural (HMF) and diastase activity.

- DNA analysis of Manuka pollen.

- Moisture content and microbiological safety.

After initial testing, the barrels are stored in temperature-controlled facilities and regularly sampled to maintain ongoing quality assurance.

MPI-Compliant Testing and Certification

MNZ adheres strictly to the 2017 MPI definition for Manuka honey, which requires the presence of five science-based markers to authenticate genuine New Zealand Manuka honey. These include:

- Chemical markers: 3-Phenyl-lactic acid, 2-Methoxyacetophenone, 2-Methoxybenzoic acid, and 4-Hydroxyphenyl lactic acid.

- DNA marker: Manuka pollen DNA analysis.

Only honey that meets these stringent requirements is certified for export as New Zealand Manuka honey.

Batch Processing and Rigorous Testing

Our batch processing system ensures that every jar meets exacting standards:

- Honey barrels are selected based on required quality parameters.

- Continuous visual inspections and laboratory analysis are conducted during processing.

- All batches undergo rigorous internal and external testing through IANZ-certified laboratories to verify MPI specifications, including:

- Color.

- Conductivity.

- Taste and aroma.

- Presence of Manuka-type pollen.

- Levels of MGO and DHA.

Batches are only released for labeling and shipment once all testing criteria, production data, and origin documentation meet regulatory and market requirements.

Commitment to Transparency and Global Compliance

Each batch is issued a comprehensive analysis certificate, guaranteeing its quality. MNZ also participates in the E-Certificate of Official Assurances program, ensuring international compliance with the Overseas Market Access Requirements (OMAR). This includes electronic certification for shipments to the EU and other treaty-bound nations, offering unmatched reliability and assurance.

MNZ: Setting the Standard in Raw Monofloral Manuka Honey

RMP-Certified Processing Excellence

MNZ operates under a Risk Management Program (RMP) for the processing of bee products, ensuring compliance with New Zealand’s strict food safety and quality standards. Our laboratory testing is conducted in IANZ-certified (ISO 17025) facilities, guaranteeing accuracy and reliability in every analysis.

100% New Zealand Made, 100% BPA-Free

MNZ exclusively produces raw, monofloral Manuka honey in BPA-free packaging, ensuring our commitment to both product integrity and environmental sustainability. Every step—from production and processing to packaging—is proudly carried out in New Zealand, preserving the natural quality and authenticity of our honey.

Pure, Raw, and Natural

MNZ’s monofloral MGO Manuka Honey is:

- Raw: Retaining all natural enzymes, nutrients, and bioactive compounds.

- Unfiltered: Free from excessive processing to preserve its natural properties.

- Unpasteurized: Maintaining the integrity of its unique bioactive qualities.

With MNZ, you can trust that every jar delivers pure, unaltered Manuka honey, crafted with care and backed by the highest standards of quality and safety.

Information from MNZ on pesticides and herbicides related to manuka honey

Rigorous Quality Control

At MNZ, we uphold a strict quality control process that ensures all Manuka honey meets the highest standards before entering or leaving our packaging facility. Each batch is tested for a comprehensive range of parameters, including:

- Microbiological elements

- Toxins

- Sugars

- Pollen content

- Moisture

- Flavor and color

- Enzyme activity

These tests comply with the requirements set by the New Zealand Ministry for Primary Industries (MPI), ensuring consistency and safety in every jar of MNZ Manuka honey. In addition to our own rigorous monitoring, MNZ participates in MPI’s national screening program, which includes testing for chemical residues as outlined in Section 8.0 of the MPI Consolidated List of Tests for Animal Products.

Commitment to Bee and Pollinator Protection

MNZ recognizes the vital role of bees and pollinators in preserving biodiversity and food security. Our operations are guided by New Zealand’s strict environmental regulations, supervised by:

-

The New Zealand Ministry for Primary Industries (MPI):

- Oversees the national food safety system and sets industry standards.

- Implements a robust chemical residue testing program for honey and other animal products.

-

The New Zealand Environmental Protection Authority (EPA):

- Protects pollinators, including bees, moths, butterflies, hoverflies, and birds.

- Sets and enforces rules on the use of insecticides, including neonicotinoids, with specific measures to safeguard pollinator health.

Remote, Sustainable Beekeeping

To ensure the purity of our raw, monofloral Manuka honey, MNZ strategically places its wooden beehives in remote, untouched locations far from agricultural lands. These pristine areas minimize exposure to herbicides, pesticides, and other environmental contaminants, guaranteeing honey that is as pure as nature intended.

Information from MNZ on raw manuka honey

At MNZ, we produce only raw, unfiltered, and unpasteurized monofloral MGO Manuka honey, preserving its natural properties and delivering honey as nature intended. A hallmark of truly raw honey, crystallization is a natural and beneficial process that reflects the purity and quality of the product.

The Science Behind Crystallization

Honey is a super-saturated sugar solution, containing over 70% sugars and less than 20% water. At the hive’s warm environment (approximately 35°C / 95°F), honey remains stable in its liquid form. However, at lower temperatures, the glucose within honey begins to crystallize, forming a solid structure.

Crystallization:

- Preserves flavor and quality by maintaining the honey’s natural properties.

- Varies in texture based on honey type:

- Some honeys form small, fine crystals for a smooth texture.

- Others develop larger, granular crystals.

- Affects appearance as crystallized honey becomes lighter and more opaque, with glucose crystals appearing pure white.

In raw Manuka honey, crystallization often creates a firmer texture compared to other honey varieties due to its unique composition and natural bioactive properties.

White Residue: A Sign of Purity

White residue or crystallization in raw Manuka honey is completely natural and indicates its raw, unprocessed state. If desired, crystallized honey can be returned to its liquid form by gently warming the jar in warm water (max. 35°C / 95°F).

Traditional Centrifugation: The Extraction Process

MNZ uses the traditional method of centrifugation to extract honey. This process:

- Removes larger wax pieces while retaining smaller natural particles.

- Ensures a cleaner honey without exposing it to heat, preserving its natural enzymes and bioactive compounds.

- Keeps the honey’s natural texture, aroma, and taste intact.

Pure and Unaltered

MNZ’s commitment to producing raw, monofloral MGO Manuka honey ensures that every jar reflects the highest standards of purity and quality. Crystallization is not a flaw—it’s a testament to the honey’s natural origins and its raw, unprocessed state.

Characteristics of raw honey

Unmatched Quality and Nutritional Benefits

MNZ’s raw MGO Manuka Honey is crafted to retain its exceptional natural properties:

- Vitamins, minerals, and nutrients remain intact for maximum health benefits.

- Higher natural enzyme content enhances its bioactivity.

- High amino acid profile supports overall wellness.

- Thicker consistency with a slightly grainy texture adds richness and authenticity.

- Incredible aromas and natural flavor profile offer a truly unique taste experience.

The 4-Step Production Process

MNZ ensures the integrity of every jar through a meticulous, cold-processing method that preserves the honey’s natural bioactive properties:

-

Cold Extraction:

Using a cold extraction method (max 35°C / 95°F), honey is carefully extracted from the honeycombs to maintain its raw, natural state. -

Collection:

The extracted honey is collected into large, food-grade honey barrels, ensuring a seamless process that retains purity. -

Light Filtration:

Honey is lightly filtered to remove any stray wax or bees, ensuring a clean, pure product without compromising its raw, unprocessed nature. -

Jar Filling:

The honey is carefully filled into jars, untouched by pasteurization or heat, preserving its natural, unaltered state. Each jar contains pure, raw, unprocessed, unpasteurized, and unheated Manuka honey, just as nature intended.